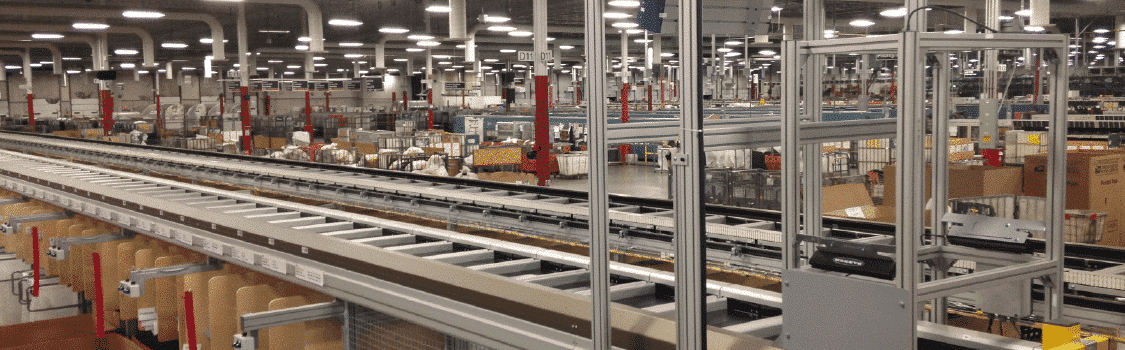

As package volumes climb, so too has the U.S. Postal Service’s investments in sorting systems. Since 2015, it has deployed 33 Small Package Sorting System (SPSS) machines costing over $141 million. It intended to invest another $23 million to have seven more SPSS machines operational during the current holiday season.

As package volumes climb, so too has the U.S. Postal Service’s investments in sorting systems. Since 2015, it has deployed 33 Small Package Sorting System (SPSS) machines costing over $141 million. It intended to invest another $23 million to have seven more SPSS machines operational during the current holiday season.

The SPSS machine was designed to support package delivery by automating package sorting, alleviating existing processing capacity shortfalls, and reducing manual sorting. We recently conducted an audit to evaluate the throughput and productivity performances of the 33 deployed SPSS machines. Throughput is the average number of packages sorted in an hour. Productivity is the average number of packages sorted per employee workhour.

We found that, on average nationally, the SPSS machines exceeded their throughput performance goal by about 5 percent from January 1, 2016, through July 31, 2017.

- Throughput goal was 4,500 packages per hour.

- The achieved throughput was 4,737 packages per hour.

- 23 of the 33 SPSS machines exceeded the goal with the other 10 falling below the goal.

When we measured average national machine productivity in the same period, however, we found the Postal Service fell short of its goal by 17 percent:

- SPSS productivity goal was 385 packages per labor hour.

- The achieved productivity was 319 packages.

We ultimately recommended better supervision and planning to improve SPSS productivity and throughput, including that management ensure staffing matched package volume. We calculated that USPS would save about $24.8 million in labor costs annually by correcting the causes of low productivity nationally.

Do you work in a facility with an SPSS machine? If so, what are your experiences with the machines?

Source: USPS Office of Inspector General